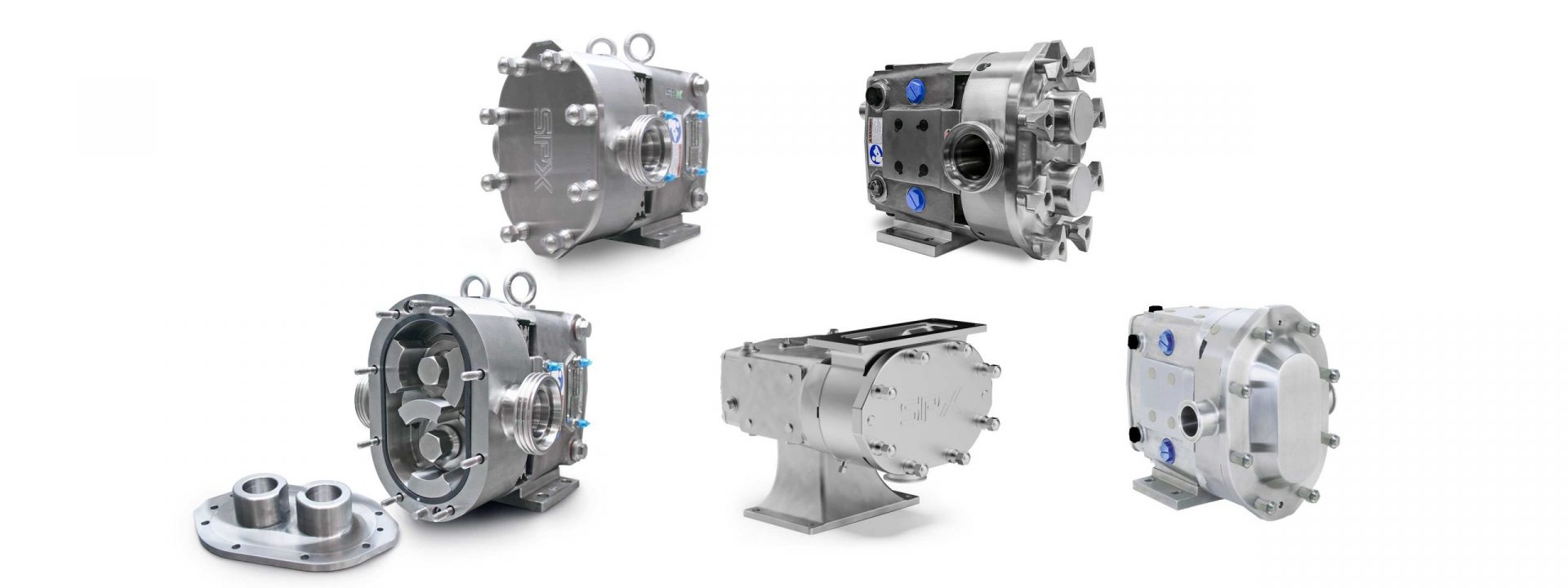

Circumferential Piston pumps

How do Circumferential Piston pumps work?

Due to their functional principle, Circumferential Piston pumps belong to the self-priming positive displacement pumps. Both the pump housing and the rotors are made of high-quality stainless steel, which makes them particularly suitable for hygienic applications. These pumps are characterised by their reliability, enable standardised cleaning procedures to be carried out and achieve high flow rates despite their compact design.

Waukesha Universal 2:

- Delivery rate max.: 150 m³/h

- Delivery pressure max.: 34.5 bar

- Viscosity max.: 1000000 cSt

- Material: stainless steel, Alloy 88, ductile iron and Tygon

- Temperature range: -40° to 149° Celsius

Waukesha Universal 3:

- Delivery rate max.: 102m³/h

- Delivery pressure max.: 34,5bar

- Viscosity max.: 1000000 cSt

- Material: Stainless steel, Alloy 88, ductile iron and Tygon

Temperature range: -40° to 149° Celsius

What are the advantages of Circumferential Piston pumps?

- Pumping of highly viscous media for food and beverage production

- Large surface seal between rotors and housing for more efficiency

- Cleaning of the pump according to standardised procedures such as CIP and SIP

- Housing and rotors made of corrosion-resistant stainless steel

Can be designed with integrated heating or cooling jacket

In which applications are centrifugal pumps used?

Circumferential Piston pumps for pumping highly viscous media

Due to the outstanding pumping characteristics, Circumferential Piston pumps are used for pumping butter. The pump can be designed with an enlarged inlet to convey the cold high-viscosity butter to the packaging plant.

Conveying of shear-sensitive media

Circumferential Piston pumps enable the pumping of media with shear-sensitive components. Dairy products such as yoghurts often contain shear-sensitive components such as fruit puree, which must be transported as gently as possible.

Ideal for pumping aseptic media

In addition, Circumferential Piston pumps can be integrated into the manufacturing process of aseptic products such as emulsions. Standardised cleaning technologies according to CIP and SIP ensure a contamination-free product chamber and consistent product quality.

Product overview and flyer for download

Ateliers Ehrismann

Quality since 1923

Contact in Switzerland and Europe

Ateliers Ehrismann has been ensuring the highest manufacturing quality at its site in Switzerland since 1923. Together with our strong partner the AxFlow group of companies, we are represented not only in Switzerland but throughout Europe.

Individualization is our strength

Ateliers Ehrismann has one of the most modern workshops in the field of electrical engineering and metal construction. Customer orders can thus be designed to meet all individual requirements.

Certified several times

The outstanding manufacturing quality is certified several times. We can manufacture and repair process equipment, for complex and highly sensitive industrial applications. Our quality management continues to constantly optimize the processes in the areas of purchasing, manufacturing and service management in order to remain the first point of contact in Switzerland and Europe in the future.

FAQ`s

Frequently asked questions

In contrast to Circumferential Piston pumps, rotary lobe pumps allow a larger surface seal in the delivery chamber. This means that shear-sensitive media can be pumped more gently. In addition, Circumferential Piston pumps are able to reliably convey media with high viscosities of up to 1,000,000 cSt.

Circumferential Piston pumps can be designed with an integrated heating or cooling jacket, which is supplied via an independent liquid circuit to ensure the desired temperature level of the medium. The aggregate state of the medium thus remains unchanged during the entire application and ensures constant product quality.

Circumferential Piston pumps have various hygienic connection options. Especially for highly viscous media, the pump technology can be designed with a rectangular flange.