Manufacturing of small and large mechanical components

With our manufacturing presence in Switzerland, we have the capabilities to produce small and large mechanical components from all machinable materials. In the areas of drilling, turning and milling, the most modern technologies are used, which enable the production of blanks, spare parts, complete systems or small series.

Production of spare and wear parts

Due to our manufacturing presence, we have the resources to handle repair and maintenance requests in addition to manufacturing components. Motors, pumps and other process equipment can be repaired and serviced at our facility. If spare and closure parts are no longer available from manufacturers due to a lack of product capacity, we rebuild these parts in our mechanical manufacturing facility.

Process flow

Ateliers Ehrismann works closely with you throughout the entire process cycle. Starting with the planning and ending with the finishing of the components, direct communication is the key to success for us.

Planning, manufacturing and finishing - Proven processes for over 100 years

Planning & Organisation

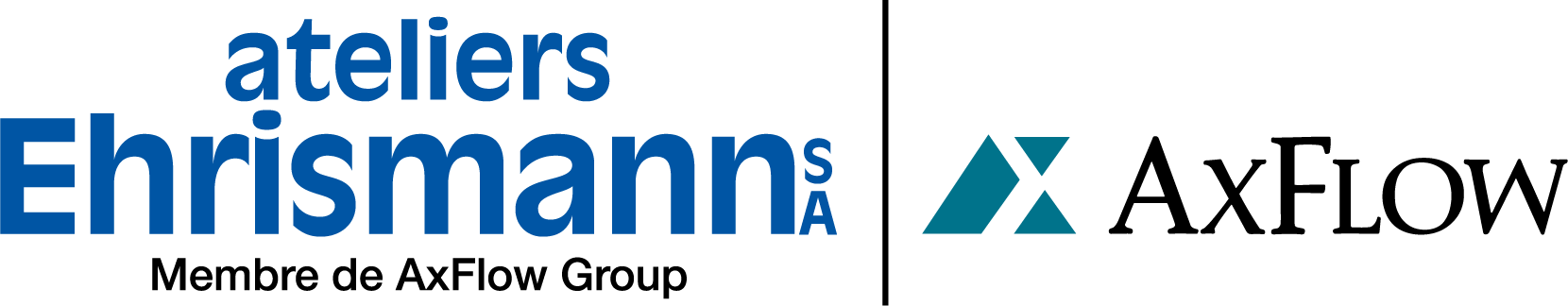

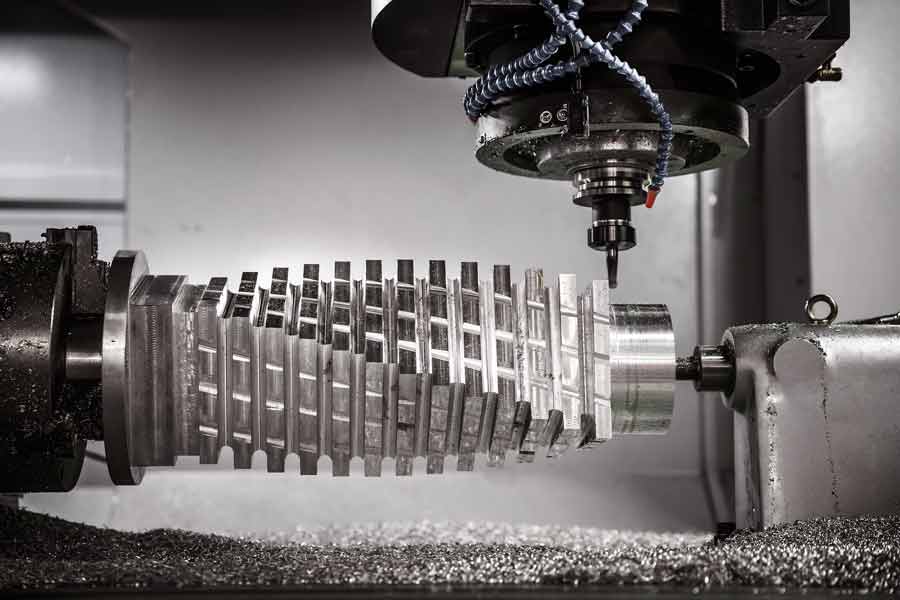

Manufacturing

Finishing

Our manufacturing processes - precision and quality from Switzerland

Drilling is considered one of the oldest process technologies in the field of mechanical manufacturing. Ateliers Ehrismann offers a variety of drilling methods: Form drillingDrilling process with controlled cutting or feed motion to produce internal surfaces that deviate from the circular-cylindrical shape CounterboringRotary movement to produce a right-angled plane surface Profile drillingMethod of producing rotationally symmetrical internal surfaces determined by the main cutting edge profile of the tool Circular drillingDrilling process for producing a circular cylindrical inner surface coaxial with the axis of rotation of the cutting movement ScrewdrivingUsed to create internal screw surfaces (e.g. threads) – feed rate is identical to the thread pitch |  |

Turning is a cutting process in which a workpiece is machined by a cutting motion of a tool. State-of-the-art machines allow us to offer a wide variety of turning techniques: Long TurningWorkpieces can be made from long and slender parts, such as wire or bar stock. FacingIn facing, the turning tool creates a cutting motion on the workpiece. In doing so, the bit rotates parallel to the axis of rotation of the shape being machined. Parting offThe process technology enables us to machine workpieces axially as well as radially. Consistently high feed rates guarantee an increase in productivity. |  |

In milling, the workpieces are machined by single- or multi-bladed tools. Both large and small parts can be machined using this manufacturing technique. Face millingThe milling process is used to produce flat surfaces such as shoulders, sealing surfaces on flanges or housings for electric motors. Circular millingCircular cylindrical external or internal surfaces can be produced on the workpiece. Roll millingThe process is used to create splines on gears. |  |

Grinding is a machining process that uses a multi-bladed tool. We use bonded and loose grinding tools for this purpose. Surface grindingThis manufacturing process is used for flat surfaces and enables the surface finishing of workpieces with micrometer accuracy. Cylindrical grindingThis technique is used for machining cylindrical, tapered or conical workpieces when the highest possible surface accuracy is required. |

|

Two or more materials can be joined together by welding. The manufacturing process can be divided into two types: Fusion WeldingIn this welding process, two workpieces are heated to the melting point and fused together. Pressure weldingThe materials to be welded are pressed together by machine with great force. Two materials with different melting points can be joined together. |  |