Fields of application for soap extruders

We improve your dosing and filling processes for a variety of applications with highly viscous, abrasive as well as filler-containing media.

|

|

Ateliers Ehrismann offers extruder technology for abrasive hygiene processes.

|

|

Ingredients in soap production often contain fillers or special ingredients that must be mixed correctly in the production process but not damaged.

|

|

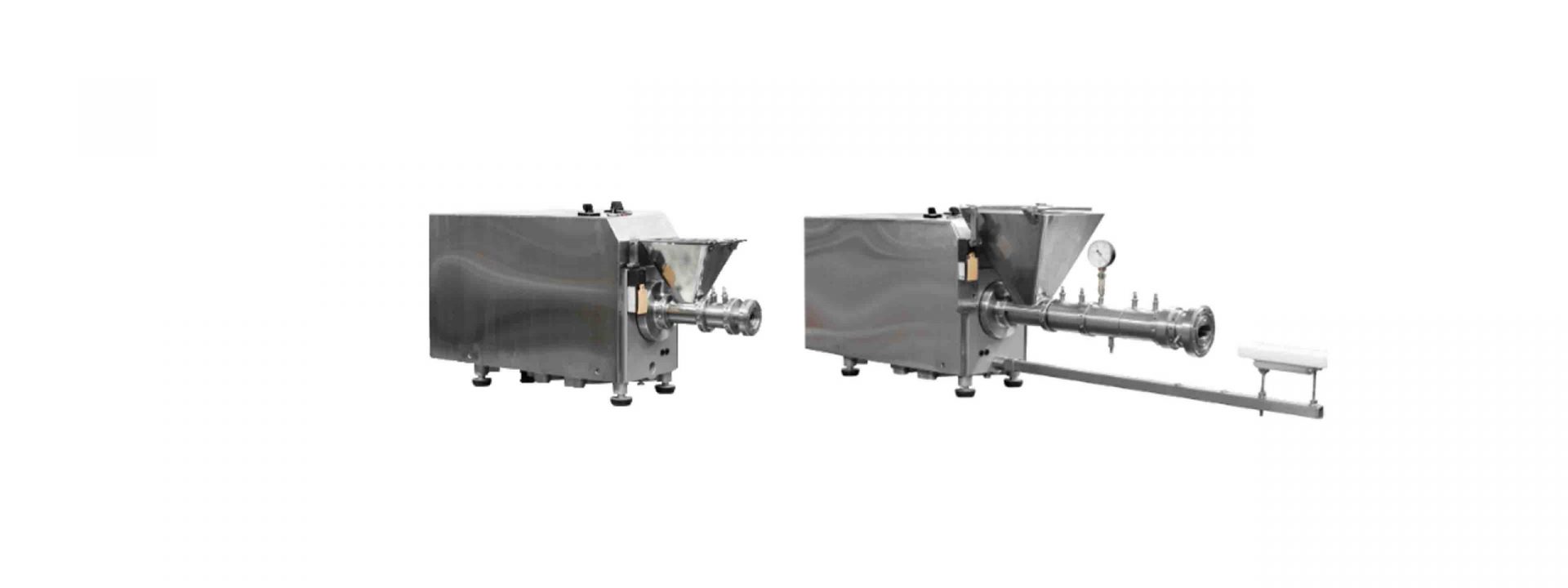

Laboratory extruder for research and development

Ateliers Ehrismann manufactures laboratory extruders that are specially designed for the research and development of flavourings and fragrances and are primarily used in the cosmetics and food industries. The process technology enables the volatile odour molecules to be combined with the fatty carrier material so that the bound molecules can be released at a constant intensity. Components such as heating and cooling jackets and degassing devices ensure consistent test conditions, which means that reproducible test series can be carried out on a laboratory scale with low material requirements.

For more than 100 years, Ateliers Ehrismann, with its manufacturing presence in Carouge, Geneva, has been offering customised customer solutions in the fields of electrical engineering and metal construction. For the best possible efficiency, we support you in the design, commissioning and servicing of laboratory extruders.

Laboratory extruder BV32

- Flow rate max.: 250 g/min

- Material: Stainless steel AISI 303, 304 & 316L

- Weight: 80 kg

Laboratory extruder BV45

- Flow rate max.: 550 g/min

- Material: Stainless steel AISI 303, 304 & 316L

- Weight: 100 kg

What are the advantages of laboratory extruders?

- Conveying and dosing of fat-containing carriers with flavourings and fragrances

- Ideal for processing granules, flakes, pellets and pasta

- Components in contact with media made of corrosion-resistant stainless steel

- Continuous pressure measurement and degassing device

- Integrated heating and cooling jacket

- Integrated intervention protection and emergency stop switch

- Low energy and wear costs

- Fully covered drive train

- Simple modular design

- Quick change of extrusion attachments

In which applications are laboratory extruders used?

Designed for development and research

Laboratory extruders are ideal for the development and research of flavourings and fragrances. Carriers containing fat, such as soap in the form of granules, flakes, pellets or noodles, are transported together with the flavour or fragrance substances via the screw conveyor and extruded through a specified outlet. This process technology binds the odour molecules in the carrier material and releases them in a controlled manner.

Ateliers Ehrismann

Quality since 1923

Contact in Switzerland and Europe

Ateliers Ehrismann has been ensuring the highest manufacturing quality at its site in Switzerland since 1923. Together with our strong partner the AxFlow group of companies, we are represented not only in Switzerland but throughout Europe.

Individualization is our strength

Ateliers Ehrismann has one of the most modern workshops in the field of electrical engineering and metal construction. Customer orders can thus be designed to meet all individual requirements.

Certified several times

The outstanding manufacturing quality is certified several times. We can manufacture and repair process equipment, for complex and highly sensitive industrial applications. Our quality management continues to constantly optimize the processes in the areas of purchasing, manufacturing and service management in order to remain the first point of contact in Switzerland and Europe in the future.

FAQ`s

Frequently asked questions

Our laboratory extruders are capable of conveying hygienic media. Components in contact with the media made of corrosion-resistant stainless steel enable the safe transport of hygienic media.

Depending on the design, our laboratory extruders can also convey a proportion of dry substance. For example, in research and development for flavourings and fragrances, fatty acids are conveyed as carrier material in the form of granules, flakes, noodles and pellets.

Our extruders are also suitable for the manufacture of other products. For example, for toothpaste or lotions. Contact us for more information on the applications of our extruders.