Peristaltic pumps

How do peristaltic pumps work?

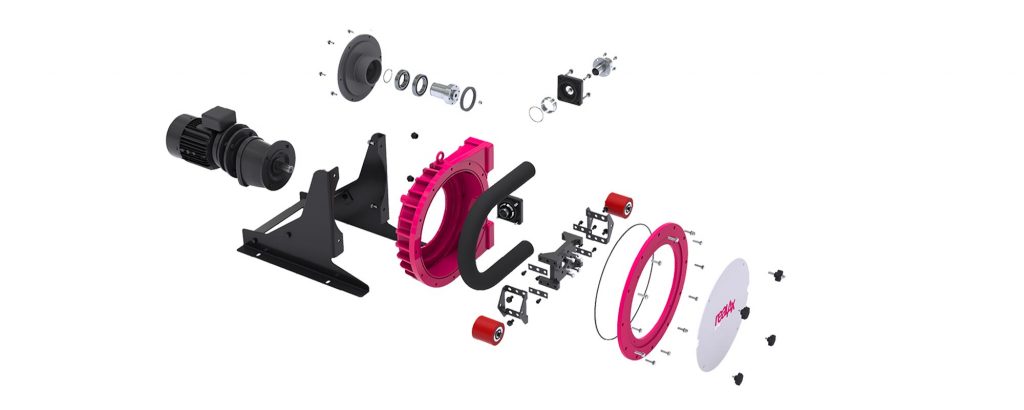

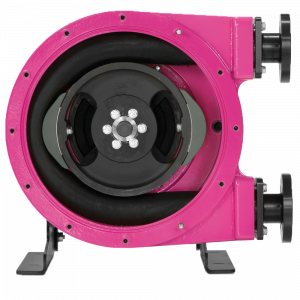

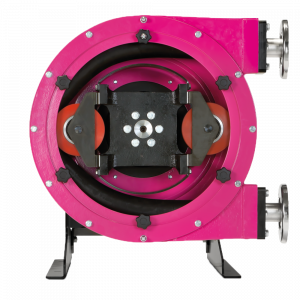

Peristaltic pumps belong to the category of self-priming positive displacement pumps. A central element of this pumping method is the hose, which is located inside the pump and through which the medium is transported. With the help of the sliding rollers or shoes attached to the rotor, the hose is compressed, which transports the medium to the pump outlet. The hose is made of different materials that ensure that it retains its original shape and properties.

realAx RP Peristaltic pumps

Sliding shoe technology:

- Delivery rate max.: 36-72 m³/h

- Delivery pressure max.: 15 bar

- Hose materials: NR, NBR, NBR for food, EPDM, CSM

realAx IP Peristaltic pumps

Sliding roller technology:

- Delivery rate max.: 1.5-42 m³/h

- Delivery pressure max.: 8 bar

- Hose materials: NR, NBR, NBR for food, EPDM, CSM

What are the advantages of peristaltic pumps?

- Pumping abrasive media containing solids

- Dry-running safe and self-priming up to 9 m

- Only the hose comes into contact with the pumped medium

- Valve-less technology reduces failures and lowers maintenance requirements

- The integrated rotor bearing reduces the load on the gearbox and motor

In which applications are peristaltic pumps used?

Peristaltic pumps in water treatment

Peristaltic pumps with sliding shoe technology are ideal for feeding filter presses. The supply or feeding of filter presses is a central process in water treatment. In this process, the sludge, which consists of abrasive, organic particles, among other things, is conveyed to the treatment plant.

Peristaltic pumps for the discharge of waste water

The self-priming positive displacement pumps can be used to discharge waste water in various industrial sectors. Sludge and suspensions with solids can be reliably pumped.

Peristaltic pumps convey abrasive media

Viscous media with solids, such as sand and rock flour, can be pumped with the peristaltic pumps. The heavy-duty hose pumps are equipped with an extremely robust hose that is reinforced several times with nylon material to withstand the high loads.

Peristaltic pumps in hygienic processes

Hygienic design of the peristaltic pumps enables their use in the food and beverage industry. Especially for pumping and dosing foodstuffs such as grape must, the pump can be equipped with FDA-compliant materials and hygienic connections.

Technical data of the realAx peristaltic pumps

Product overview and flyer for download

Ateliers Ehrismann

Quality since 1923

Contact in Switzerland and Europe

Ateliers Ehrismann has been ensuring the highest manufacturing quality at its site in Switzerland since 1923. Together with our strong partner the AxFlow group of companies, we are represented not only in Switzerland but throughout Europe.

Individualization is our strength

Ateliers Ehrismann has one of the most modern workshops in the field of electrical engineering and metal construction. Customer orders can thus be designed to meet all individual requirements.

Certified several times

The outstanding manufacturing quality is certified several times. We can manufacture and repair process equipment, for complex and highly sensitive industrial applications. Our quality management continues to constantly optimize the processes in the areas of purchasing, manufacturing and service management in order to remain the first point of contact in Switzerland and Europe in the future.

FAQ`s

Frequently asked questions

Peristaltic pumps are particularly suitable for pumping wastewater. The large performance range with a comparatively low maintenance requirement and the possibility of dry-running characterise our peristaltic pumps.

Ateliers Ehrismann can of course order spare parts from the leading manufacturers of process technology in the shortest possible time. In our European central warehouse, we keep complete, ready-to-use pumps and spare parts in stock at all times.

If you wish, our service partner will assist you with the assembly, installation and commissioning of the pump. For further information on our services, please do not hesitate to contact us.